Collection: Wall lining for professional oven connection

Wall linings are used to properly connect the stove pipes to the chimney. They are available in different diameters. Starting from 80 mm up to 250 mm. They are usually used in duplicate. This means that the wall lining has a gap into which the smoke pipe is inserted directly. Depending on where and which stove pipes are to be connected, wall linings made of pure sheet steel or fire-aluminized (FAL) sheet steel are used. The wall linings do not need to be painted because they are inserted into the wall of the chimney. If 2 mm thick steel pipes are connected, you should choose a wall lining made of sheet steel. If, on the other hand, fire-aluminized or enamelled pipes are available or the exhaust pipes are to be connected outdoors, you are better off using a FAL wall lining . FAL materials are covered with an aluminum layer and are more resistant to heat and corrosion than steel components.

Where and how are wall linings installed?

They are usually inserted directly into the chimney cheek of the chimney. They are either firmly mortared in place or wrapped in fireproof insulation beforehand. There are also special sliding wall linings with a suitable circular cutout for the fireclay pipe inside the chimney for multi-shell chimneys.

The exact position of the wall lining ultimately determines the position of the chimney and stove. Some stove owners don't like the sight of a stovepipe at all, so the rear outlet of the stove itself is used and connected straight to the chimney. This means that the wall lining sits indirectly behind the wood stove or pellet stove. For other stove fans, the smoke pipe is simply part of it and the corresponding hole in the chimney is aligned precisely with the existing stove pipes. The smoke pipes also release a small amount of heat from the exhaust gas to the installation site.

-

Double wall lining NW 80 mm for smoke pipe on NW 130 socket side stainless steel

Regular price 173,01 €Regular price -

Chimney connection smoke pipe to ceramic pipe

Regular price From 119,95 €Regular price -

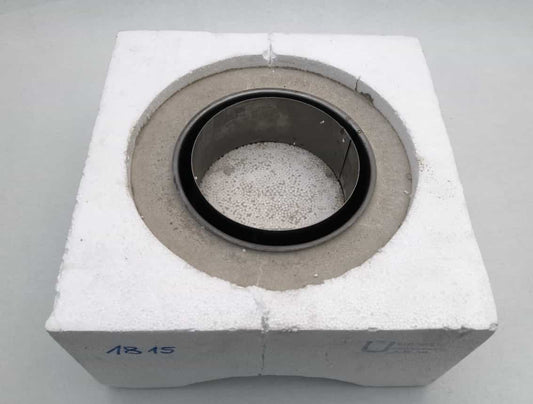

Sliding wall lining double for fireclay pipe in multi-shell chimney

Regular price From 53,95 €Regular price -

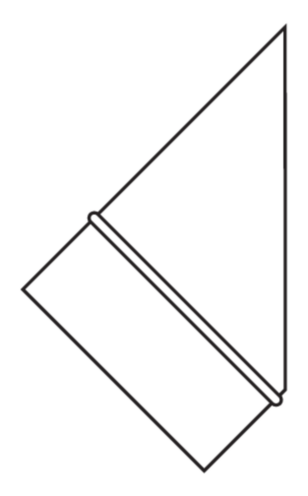

Wall lining 45° steel various diameters

Regular price From 62,80 €Regular price -

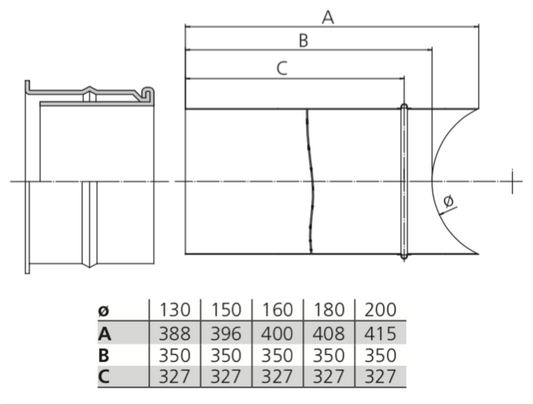

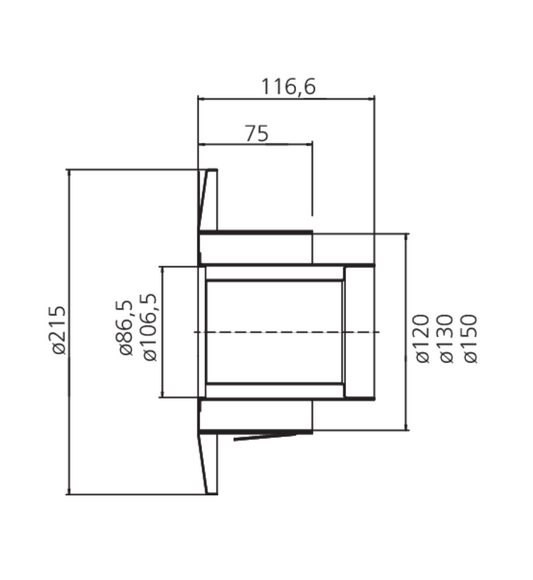

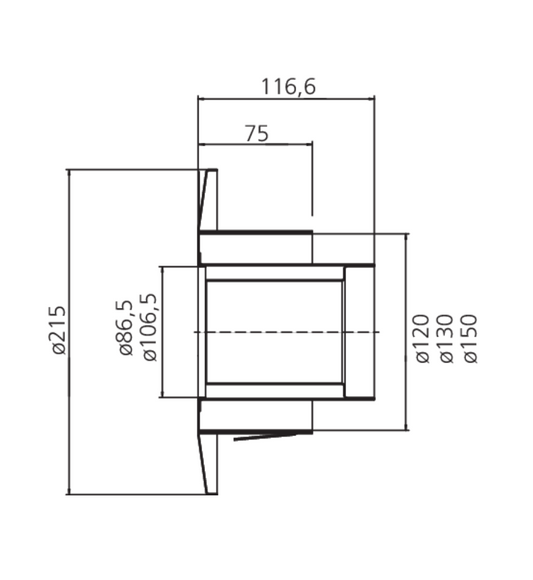

Wall lining double 12cm short FAL with Viton seal different diameters

Regular price 43,50 €Regular price -

Wall lining double 12cm short FAL different diameters

Regular price From 28,50 €Regular price -

Wall lining double 12cm short steel different diameters

Regular price From 40,95 €Regular price -

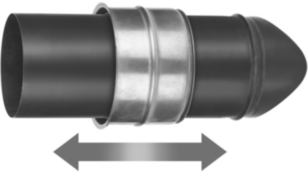

Wall lining double 40cm long can be shortened to various diameters

Regular price From 49,95 €Regular price -

Wall lining extension with rosette cast gray painted steel

Regular price From 78,90 €Regular price -

Wall lining extension with rosette in black metallic painted steel

Regular price From 78,90 €Regular price

Let customers speak for us

from 277 reviews

Die Putzkachel passt hervorragend. Gut das es noch solch einen

Onlinehandel gibt. Der Service war hervorragend und bei Fragen

war immer jemand sofort zur Stelle. Keine minutenlange Warteschleifen wie es sonst üblich ist. Volle Punktzahl.

Bin mit dem Produkt sehr zufrieden.

Die Fassade bleibt warm aber nicht heiß.

Das Hitzeschild nimmt die meiste Hitze weg!

Alles bestens 😊

Habe wie auf den Bildern zu sehen etwas gebastelt damit ich es aufhängen kann und auch mittels Kette höher oder niedriger einstellen kann.

So wie es jetzt hängt ist es aber richtig!

Vielen Dank

Sehr gute Beratung und freundlicher Kontakt. Die Kachel kam sehr gut verpackt und zügig an. Immer wieder gerne, kann ich 100%tig weiterempfehlen…!

Die von mir bestellten Ware entspricht genau meinen Erwartungen, ist qualitativ hochwertig und wurde schnell geliefert. Ich bin sehr zufrieden.

Die Tasche sieht sehr wertig aus. Sie ist größer als gedacht. Passt viel Holz hinein. Die Rollen funktionieren auch beladen einwandfrei. Keine Schlepperei mehr um das Holz in der Wohnung direkt zum Ofen zu transportieren.

Auch die Lieferung und Kaufabwicklung war top.

Zum Vergleich unsere bisherige Filztasche...

Super Produkt, sehr zu empfehlen für Holzöfen oder Kachelöfen. Brenndauer top! Preis- Leistungsverhältnis gut, schnelle Lieferung!

Schneller Versand!

Gerne wieder!

Gute Deckkraft mußte nur einmal streichen leicht zu verarbeiten. Schöne Farbe hat alles gut geklappt

Ich bin sehr zufrieden mit dem Kleber , klebt schon nach wenigen Stunden. Hält wirklich gut.

Passt perfeckt

schnell und von guter Qualität.

Sehr zu empfehlen

Sehr gut verpackt und heil angekommen!

Es war alles perfekt beschrieben und der Versand war sehr schnell alles perfekt und super Verkäufer